Tongue & Groove or Pregrooved? Nickel Gap or V-Groove? With so many terms flying about, it can be confusing trying to pick the perfect board for your project. This article aims to clear things up, explaining each of the board profiles we offer so you can make an informed, confident choice.

Profiles

A profile is the cross-section of a board when viewed from the end. It affects both the installation method and final appearance of the finished project. A profile is a combination of two factors: the joint type and the edge bevel.

Joint Type

A profile’s joint type determines how the board is installed, and how it fits together with the boards next to it. We offer the following joint types:

- Standard (S4S)

A basic rectangular board. It is fastened by driving screws through the face. Wood plugs are often used to hide the screw heads. - Pregrooved

Grooved along one or both edges for use with hidden fastener systems. No screws show in the finished project. - Tongue & Groove (T&G)

A tongue on one edge and a groove on the other. The tongue of one board fits into the groove of the one next to it. Fasteners (nails or screws) are inserted through the tongues, so they are hidden in the finished project. - Shiplap

An overhang on one edge of the board that overlaps a recessed area on the board next to it. One fastener is driven through underneath this overlap, so it is hidden from view, but another fastener must be inserted above the overlap through the visible face of the board. The visible screw heads are often hidden with wood plugs. - Rainscreen

A combination of pregrooved and shiplap. An overhang on one edge of the board overlaps a recessed area on the board next to it. Edges are grooved for use with hidden fasteners, so no screws show in the finished project. - End-Matched: Boards are milled along all four edges instead of just the two long edges. This has a distinctive aesthetic effect, but also a practical one: end joints don’t have to land on a framing member (joist or furring strip), which results in fewer cuts, less wasted material, and a faster install.

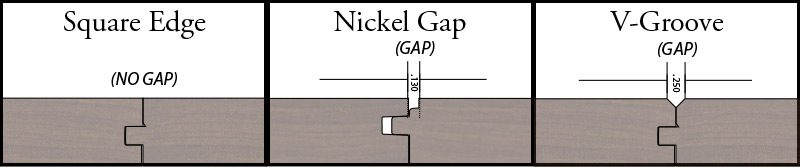

Edge Bevel

A profile’s edge bevel is a contour milled onto the edge of the board. It only affects the final appearance of the project, not the installation method. We offer the following edge bevels:

- Square Edge: Boards fit together snugly, creating a smooth surface.

- Nickel Gap: Boards edges have a rectangular bevel, which creates a narrow space at the joint, resulting in an aesthetic shadow line.

- V-Groove: Boards edges have an angled bevel, which creates a V-shaped channel at the joint.